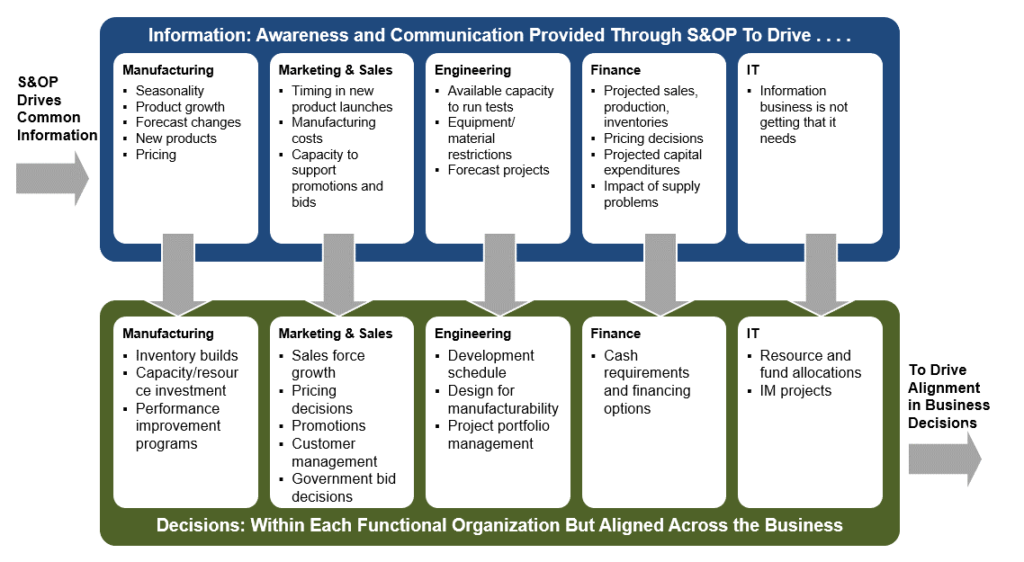

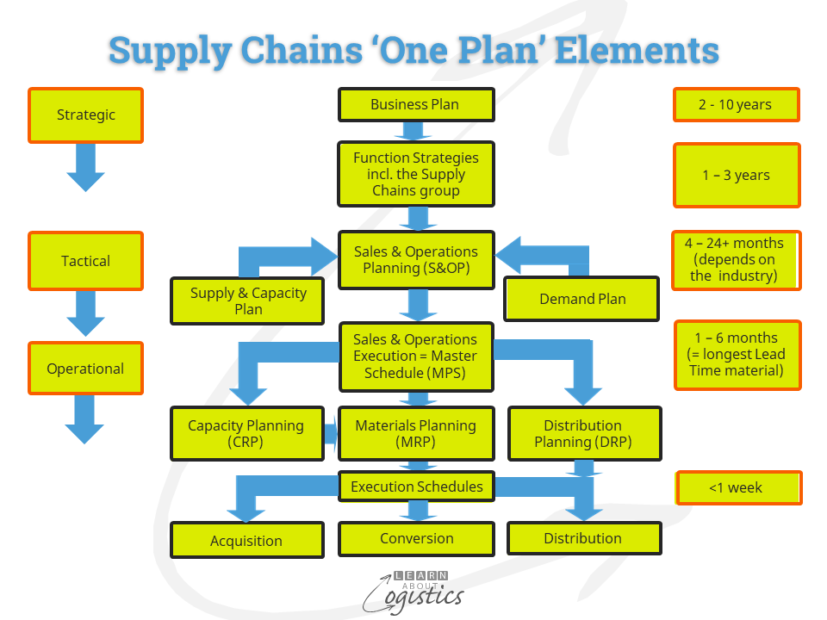

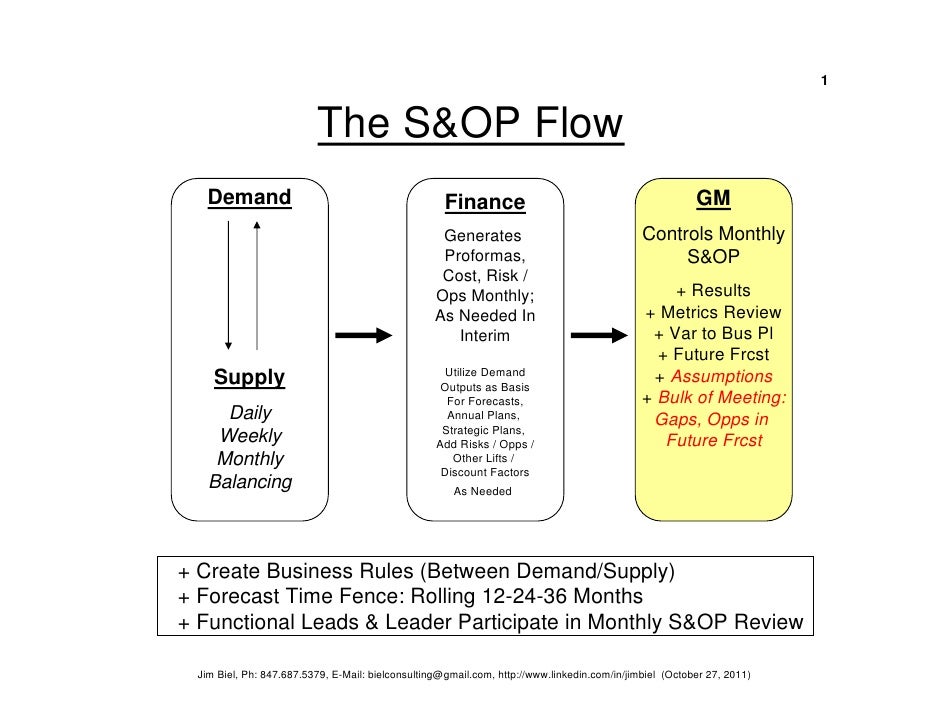

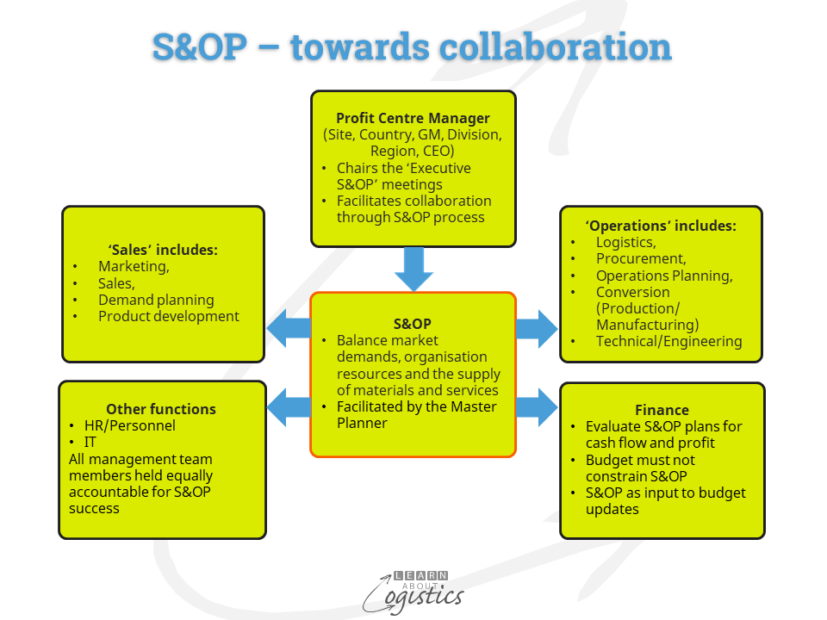

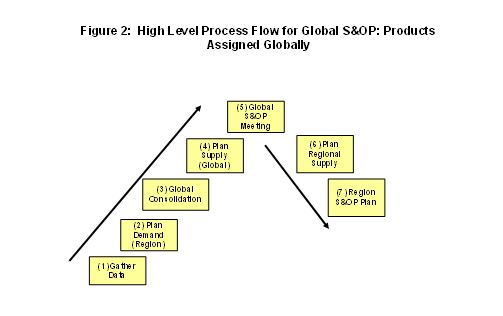

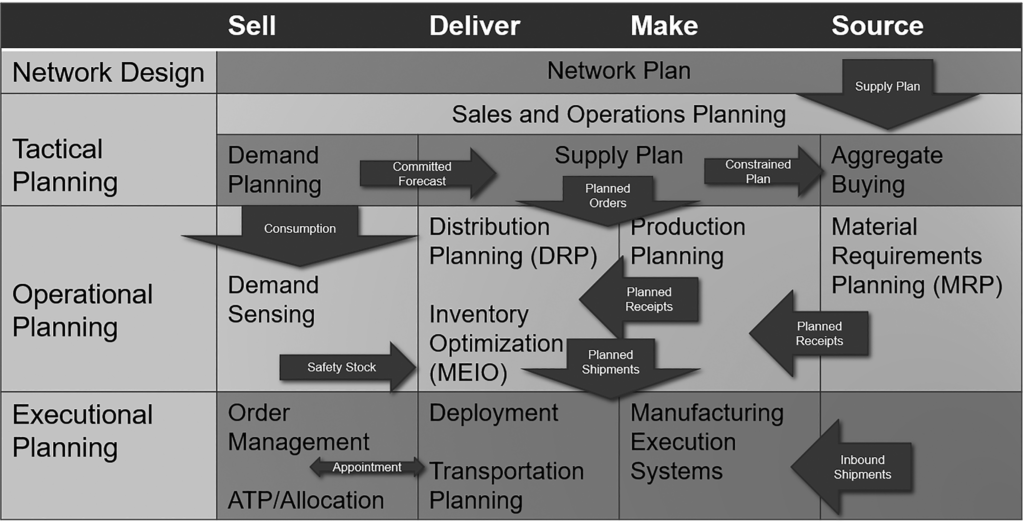

Process, must engage the general manager and direct reports Otherwise, there will be a disconnect between there wishes and the information on the formal SIOP document SIOP is not a scheduling tool!S&OP's role is to balance supply and demand at the volume level Companies who do a good job at this level find much less problem at balancing the supply and demand at mix level, thereby reducing inventory, improving customer service and improving manufacturing efficiencies Our team at Logistics Bureau have first hand experience in demystifying S&OP and making it happen withinPrimary Flow Deploying Plans Down The S&OP process operates within the bounds of the goals, targets and strategic imperatives that have been passed down from the strategic planning processes These goals, targets and strategic imperatives act as guidelines throughout the S&OP process, ensuring that decisions are being made in alignment with the agreed strategic

S Op Families By Constraint

How to implement s&op process

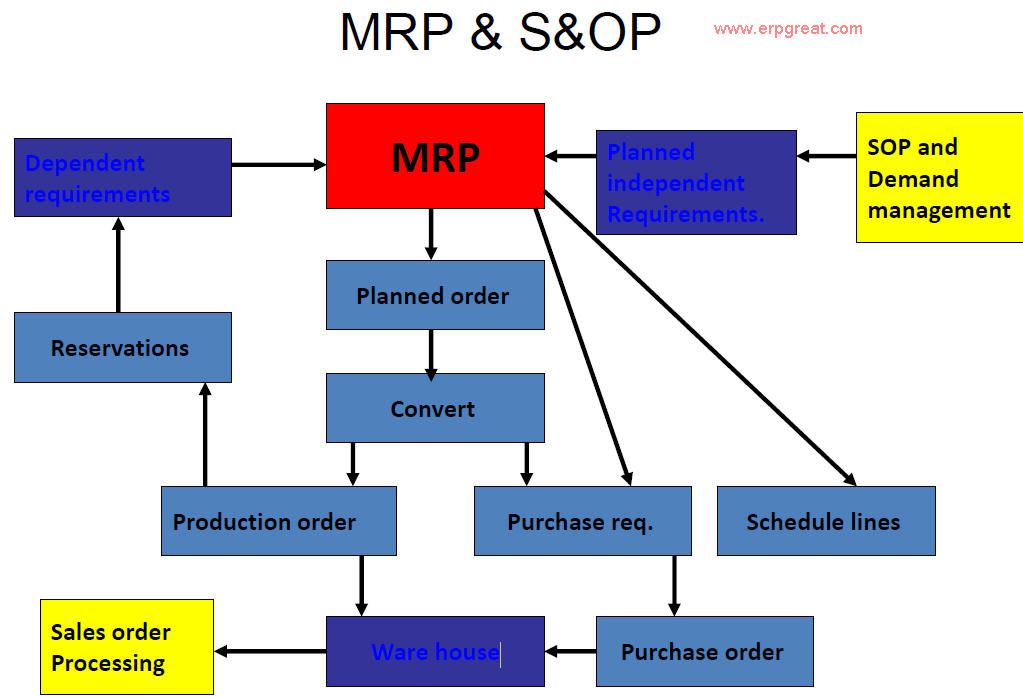

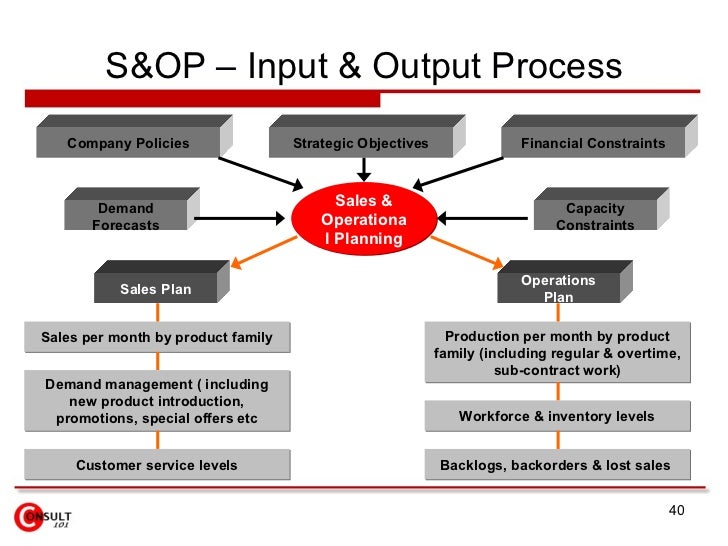

How to implement s&op process- · S&OP – Input & Output Process Company Policies Strategic Objectives Financial Constraints Capacity Constraints Demand Forecasts Sales Plan Operations Plan Sales per month by product family Customer service levels Workforce & inventory levels Backlogs, backorders & lost sales Demand management ( including new product introduction, promotions, special offers etc · S&OP is a process to help you deliver better customer service, lower inventory, shorter lead times, more stable production rates, better management control of the overall business, and a teambuilding mechanism across the whole of the senior management organisation It is a crossfunctional Planning process designed to keep demand and supply in balance This is

S Op Heuristics Flow Chart Download Scientific Diagram

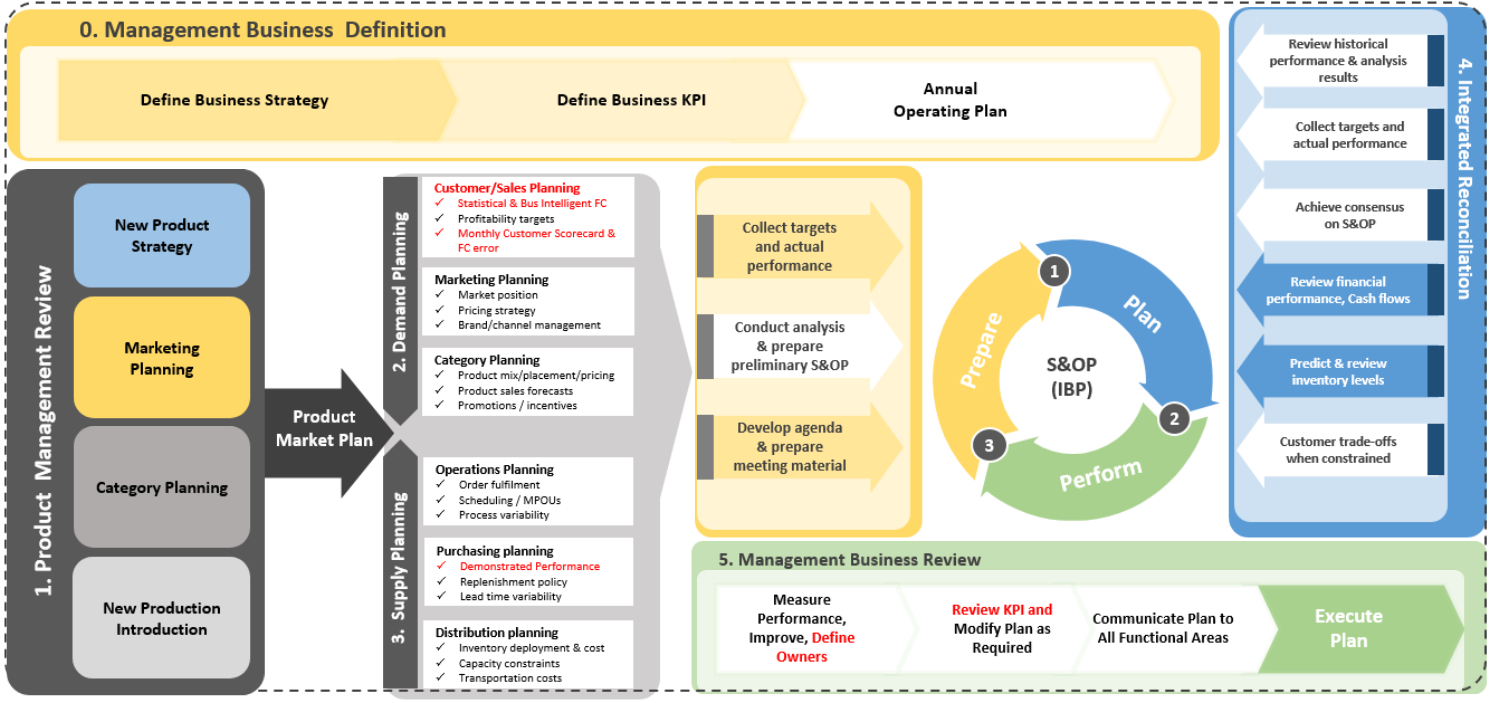

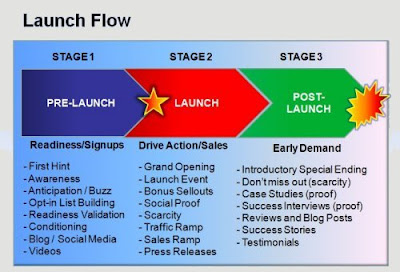

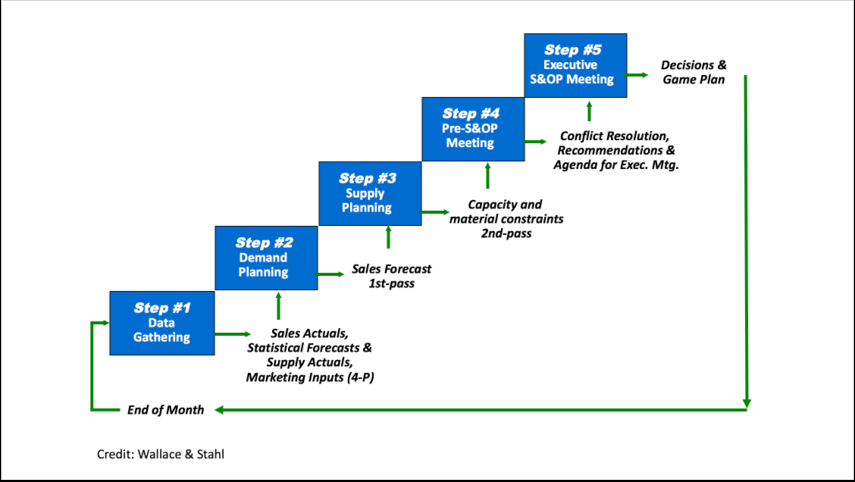

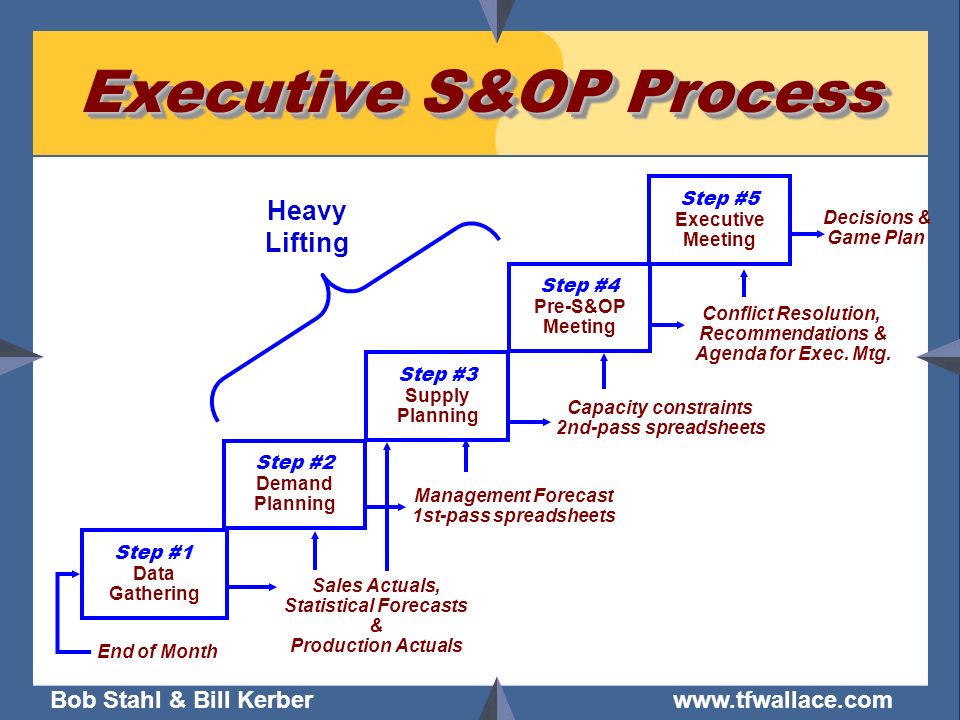

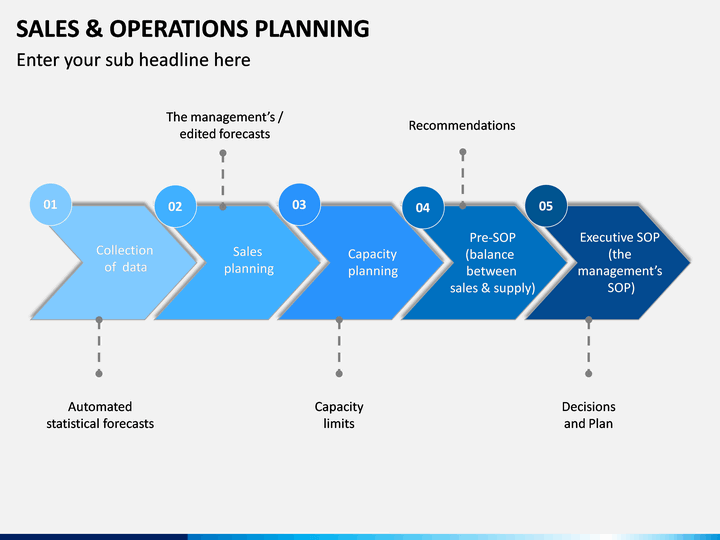

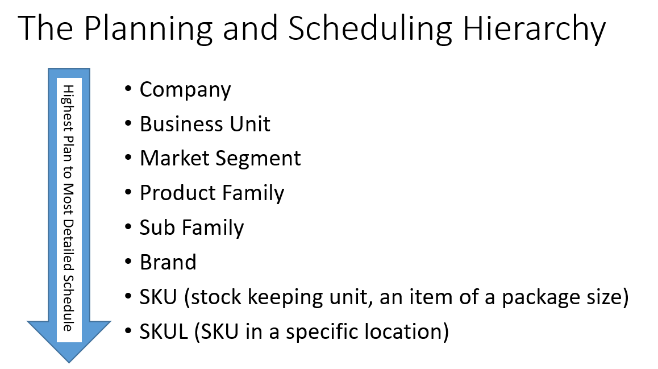

Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1S&OP Process This is a detailed Sales & Operations Financial Planning (SOFP) masterclass decribing the what, how, who, and when of the process In addition, it describes the impact of the major types of capacity planning models to the strategic planning process deployed in SOFPWe discuss what is S&OP and its components, including sales/demand planning, inventory planning, and operations planning Each part is explained in detail,

When you're implementing a new process in an organization like ours, it's quite hard to explain the business value OMP helped us convince our organization internally We now have a professional tool to show as the backbone to drive our demand planning, forecasting, and S&OP further" "In the end, the OMP solution integrated all the parts of the supply chain, from the customer demand,It is not an inventory replenishment tool!What is Sales and Operations Planning (S&OP) and why do you need it?At a recent seminar Steven Thacker explained 👇 TIMESTAMPS (in case you want to skip) 👇

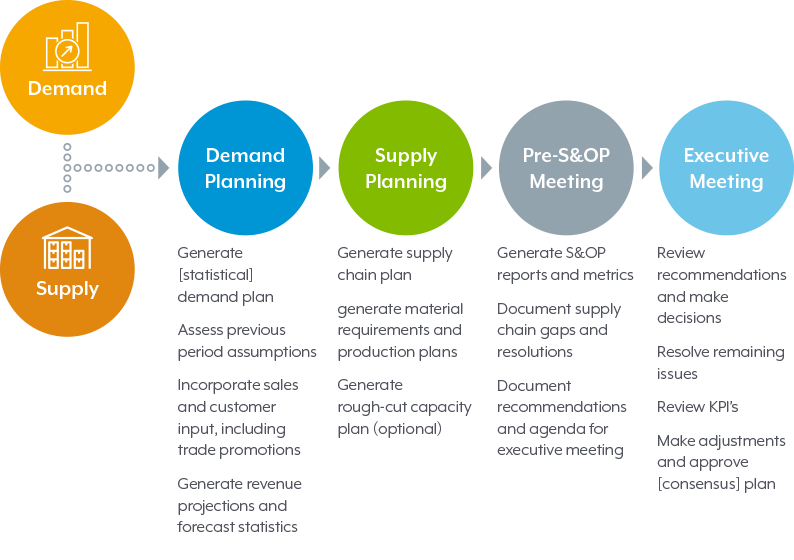

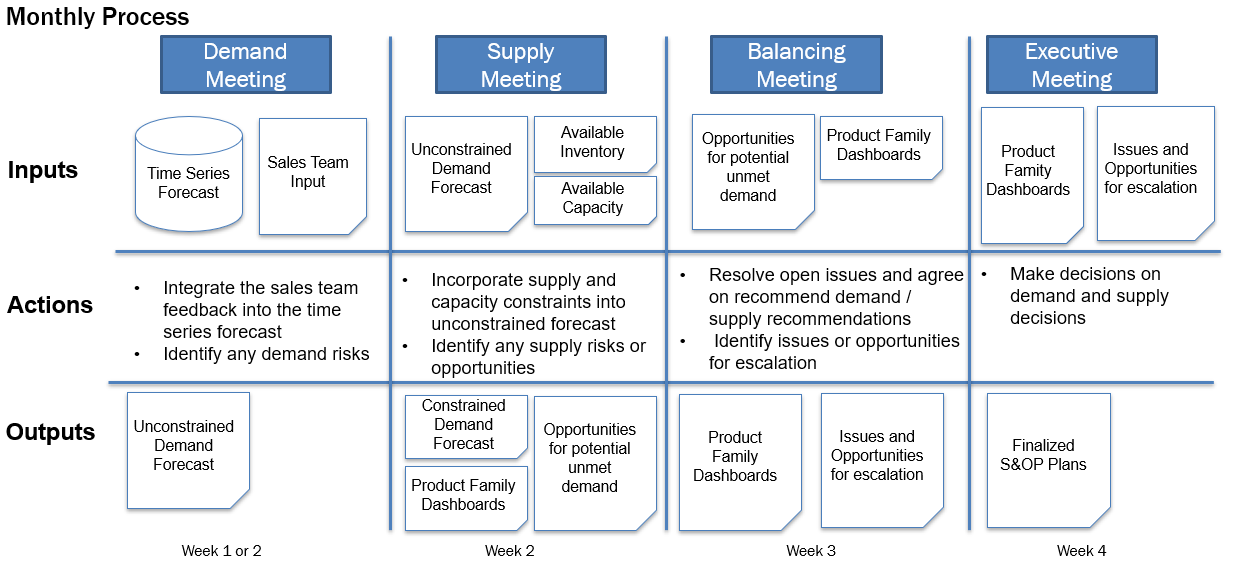

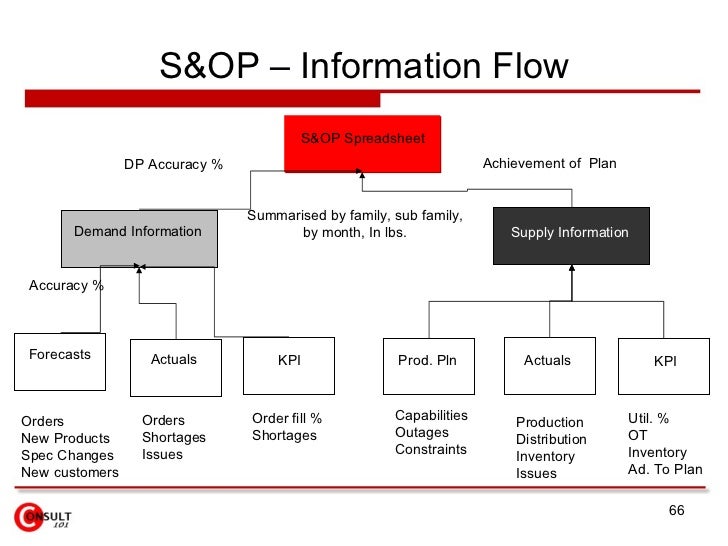

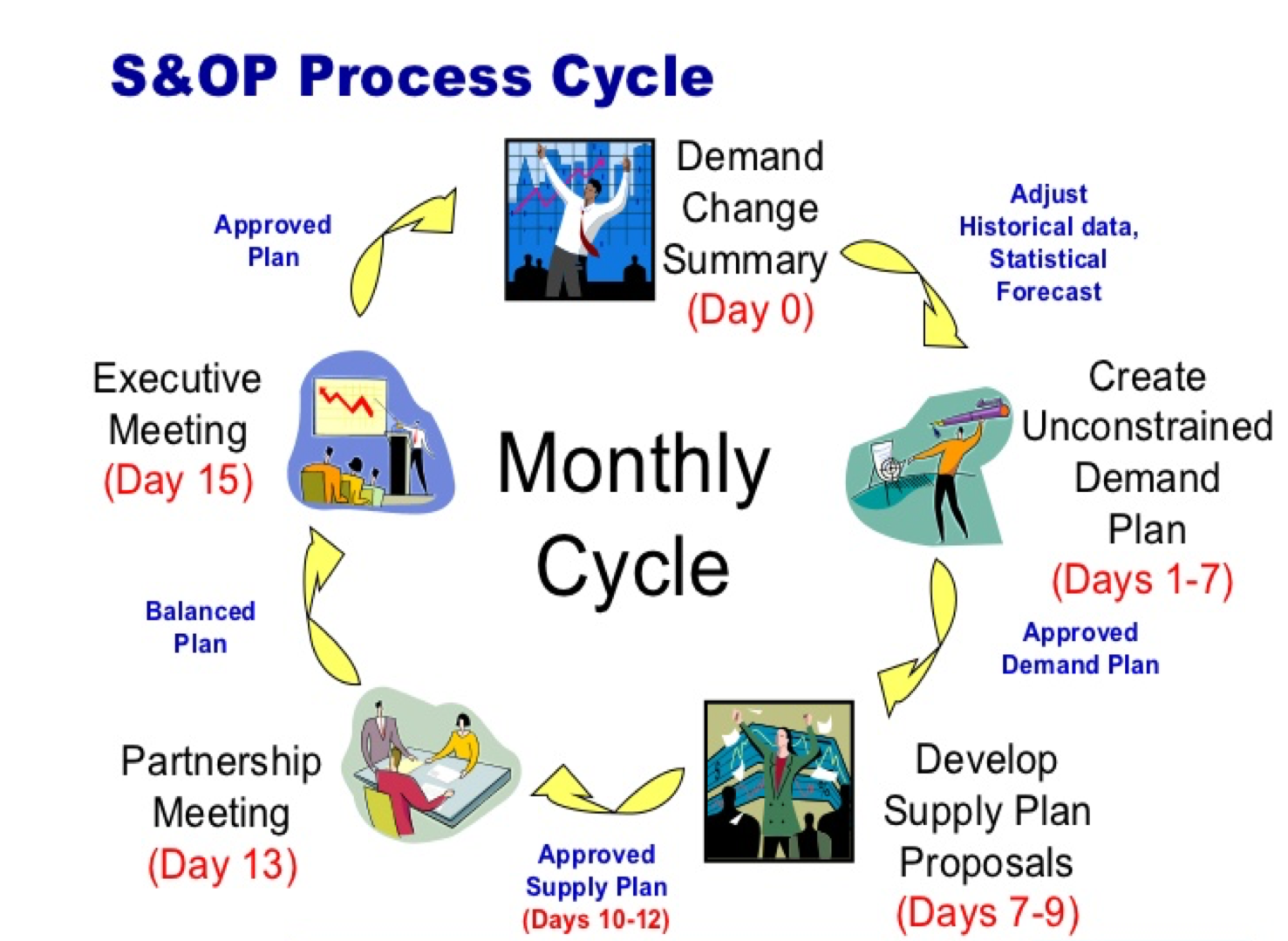

Demand Consensus dives into the details of demand generation, information aggregation, review and vetting and finally agreement on an unconstrained plan This is depicted by the first line in the chart S&OP Starts with the Demand Consensus, Supply Response to the Demand Plan, and the Gap fill process where two types of gaps are addressed · A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful business SIOP will allow you to improve your forecasting, capacity and resource planning, cash flow, and inventory levels Yet there are many challenges with getting a proper, functioning SIOP process in placeS&OP process is not dependent on industries specific characteristics It is therefore of interest to these two contradictory reconcile and investigate stances p rocess whether industries characteristics affect S&OP process and the how these characteristics should be included into a differentiated S& OP process

Gartner Blog Network

Sales And Operations Planning Process Self Assessment

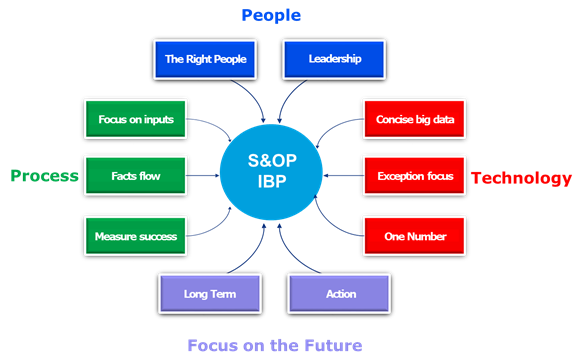

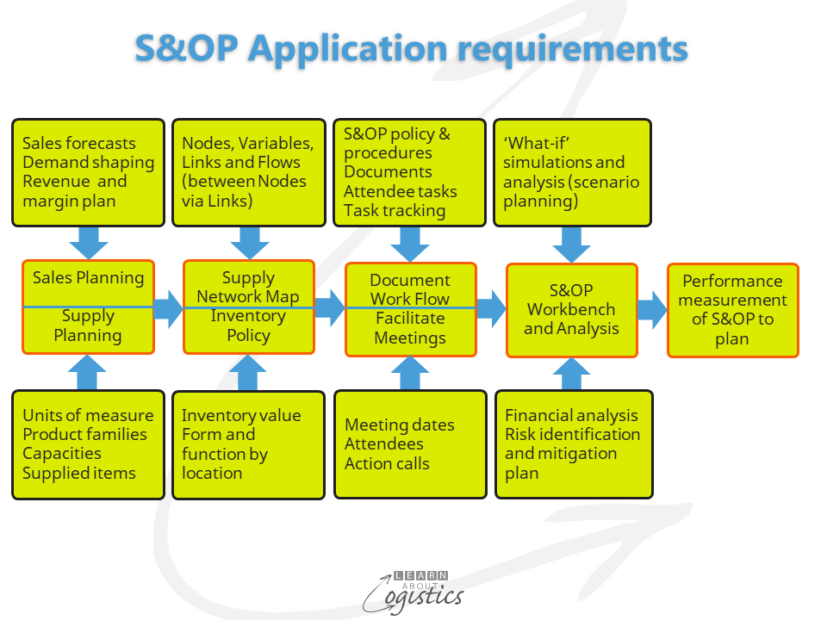

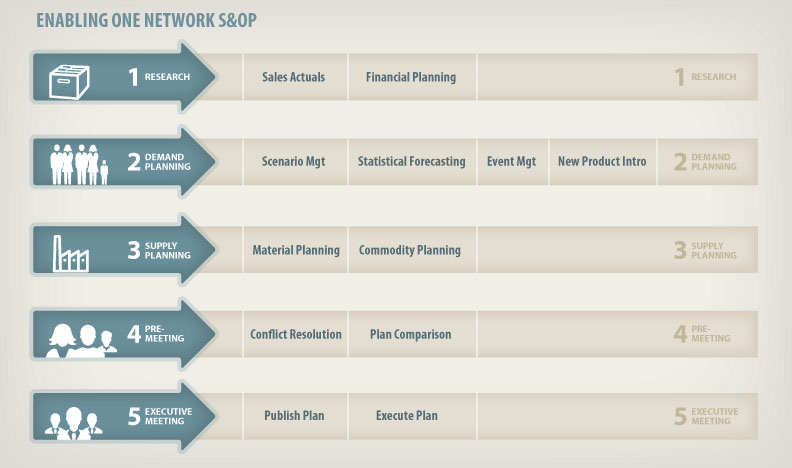

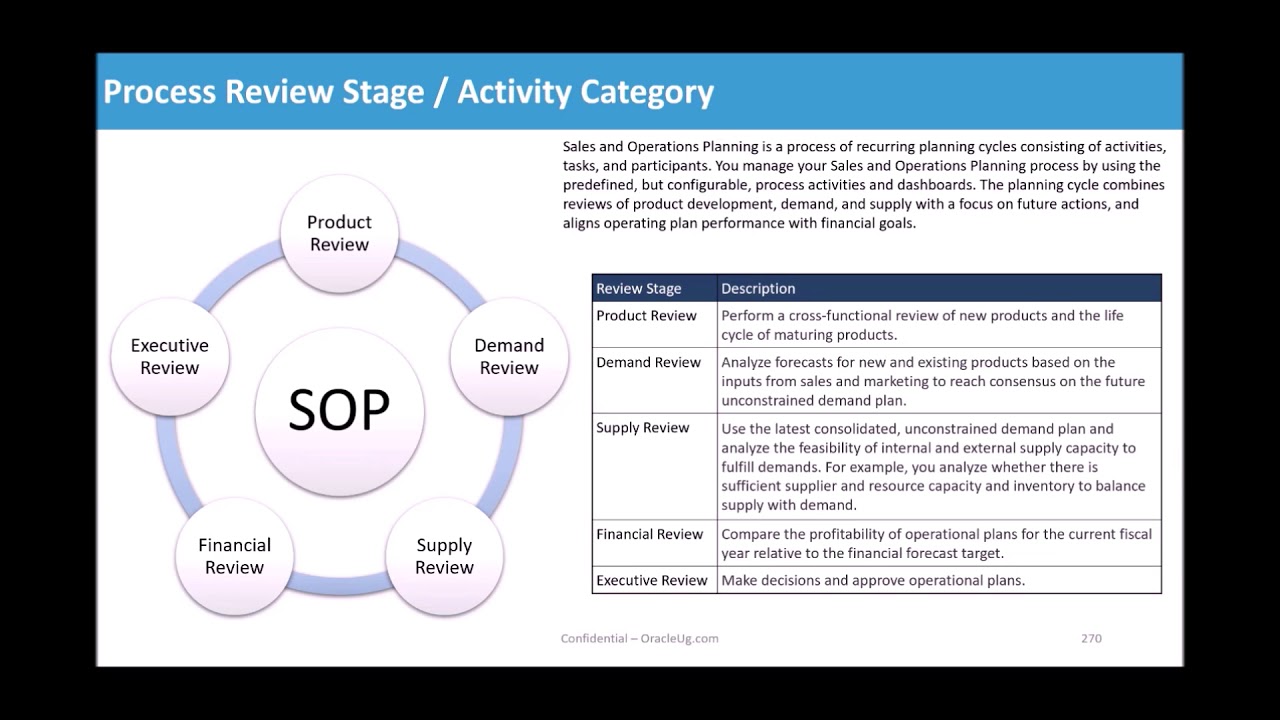

You will need to go through the validation process again nto renew with your current discount level If you are no longer academic, you can either renew as a professional without a discount or see what other discount plans you may be eligible forS&OP Application Flow at a Glance¶ A whole S&OP process includes four phases Forecast, Demand, Analytics, and Executive As might be expected, phases must be executed in sequence on any given dataset However, you can be in different phases on different datasets Users in the S&OP Process Control group will have the option to load datasets and begin the cycle To avoidSales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational tactics in all departments

Sales And Operations Planning Explorescm

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

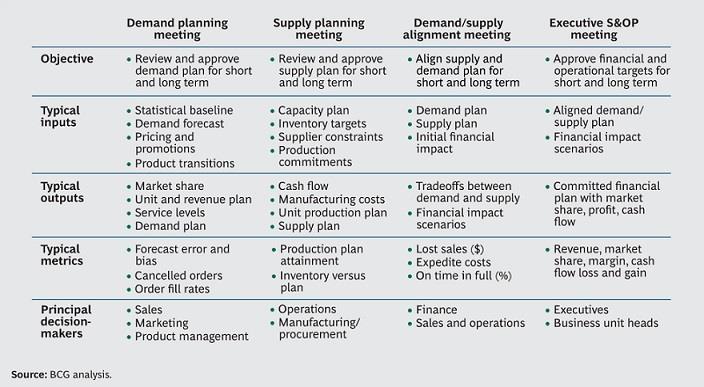

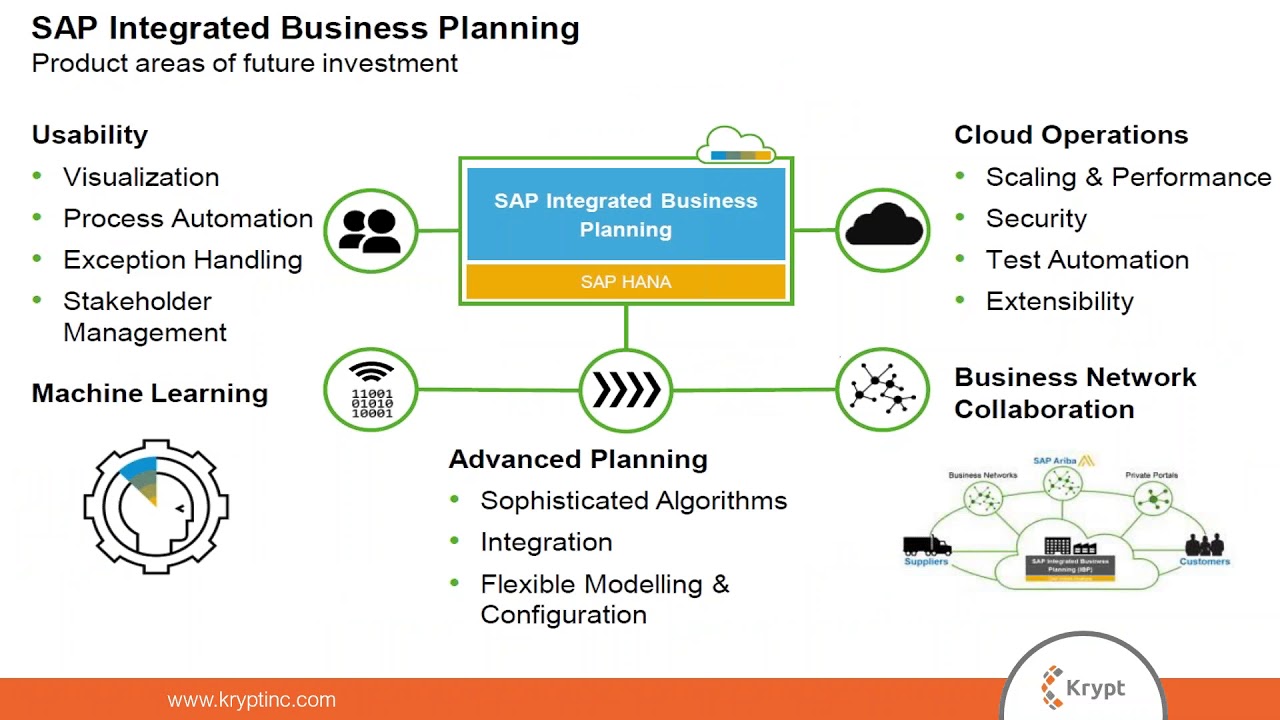

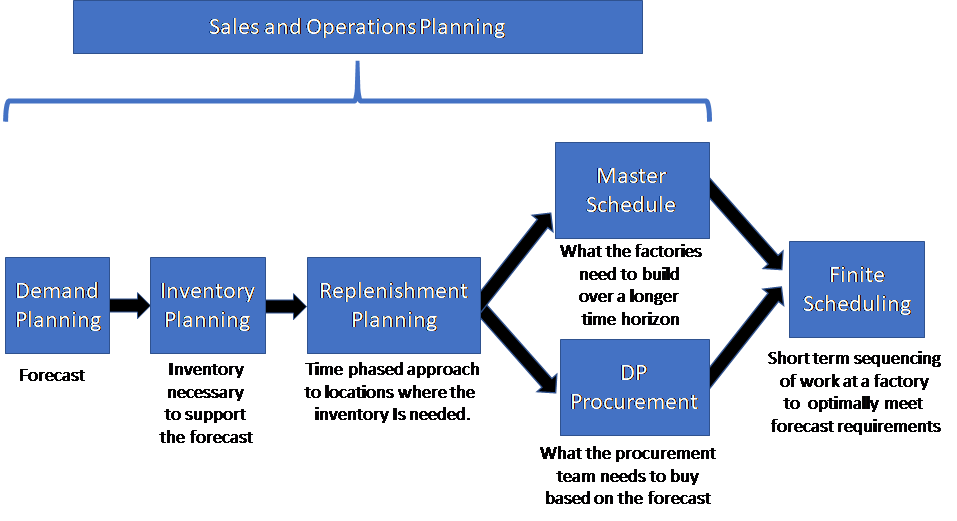

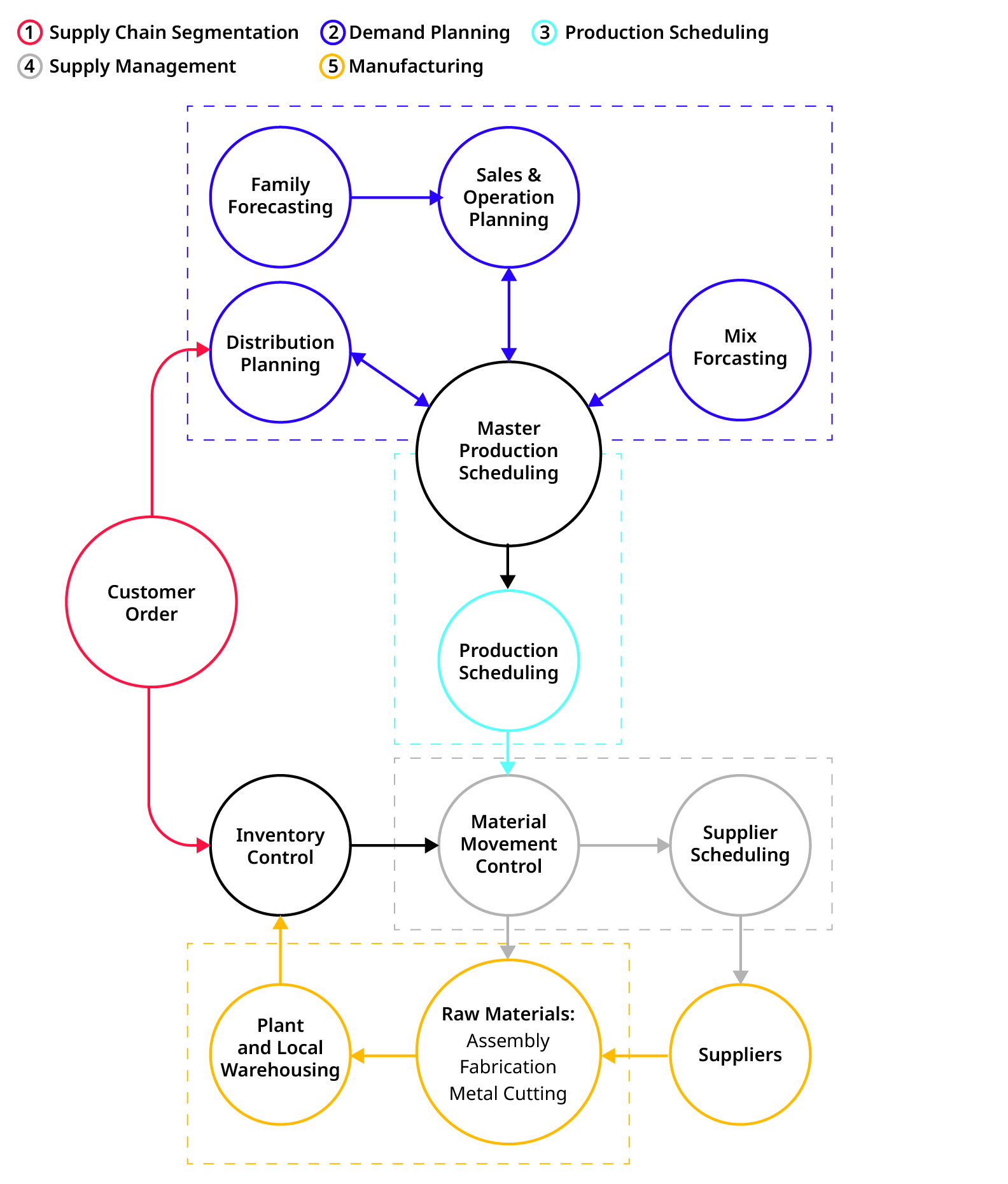

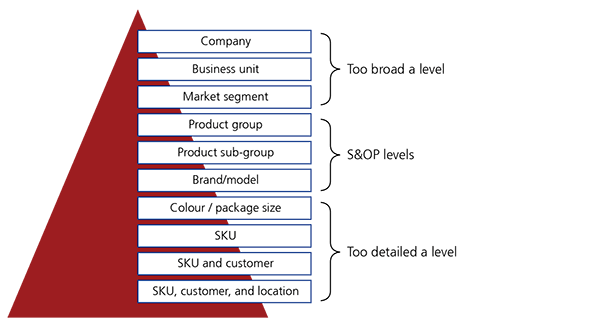

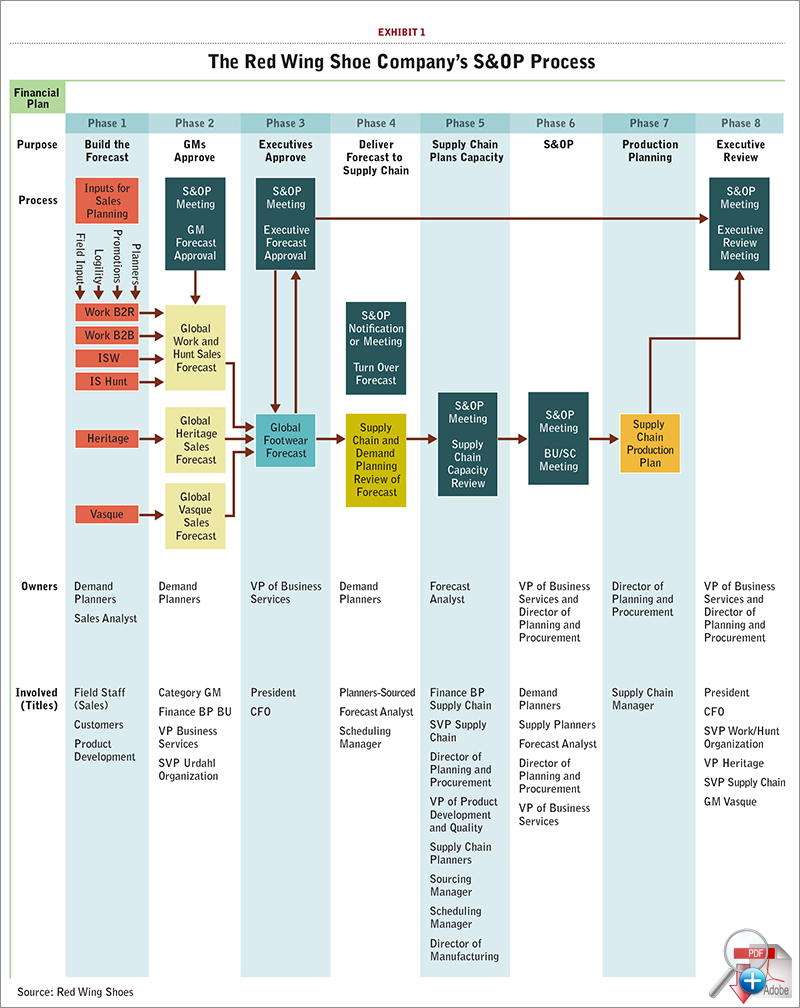

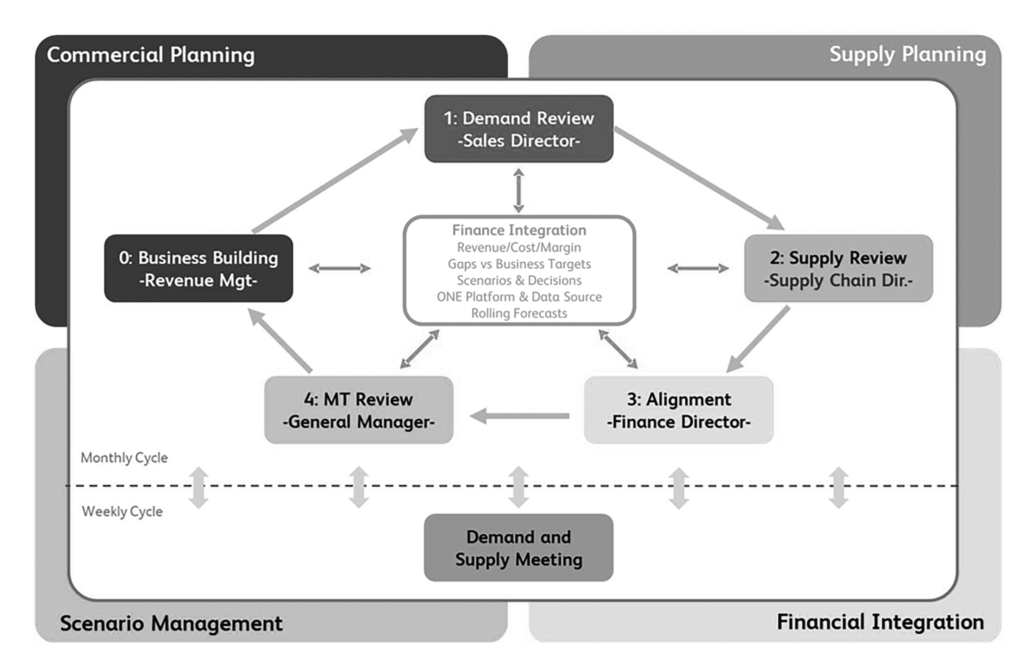

With a more mature S&OP process, it is about managing tradeoffs like these and other functions through structured process steps These usually include Product Review To discuss current and future product portfolio, New Product Launch/End of Life strategy and portfolio optimization as well as SKU complexity and component rationalization Demand Review The process through whichSales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified production plansS&OP Process flow with tools Production Disaggregation Logic Production plan @ sku level BW ECC Transportation Lane Volume TCP SAP STR's MP Production Volume SAP Planned Orders Planned Orders for Distribution and Dependent Demand BU Finance SC Finance DP SNP –Heuristics At sku level SNP –Optimizer At aggregate level AOP Version in SAP APO IP LTP SNP Output BPS

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

S&OP Integration with other Plans Source Adapted from "Operations ManagementProcesses and Value Chains", Krajewiski et al, 08, PHIL P Ltd, Milliken (07) and Lapide (04) identify S&OP asThe S&OP process needs input from and evaluation by different stakeholders Sales is normally focusing on $ and units sold per market, segment or brand Finance is focusing on $ per business group, division or region Operations is focusing on units or volume per hour per production site, capacity groups or production lines The idea of a common language in the S&OP process isThe S&OP Process 6 The solution The Seven Key S&OP Reports 13 Conclusion Summary Abstract Introduction Under intense pressure to improve service, create innovative new products, and speed delivery, the manufacturing sector remains one of the most competitive Executives need to align supply, demand, and finance plans to achieve total visibility into business performance—and

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning S Op Transform Your Business

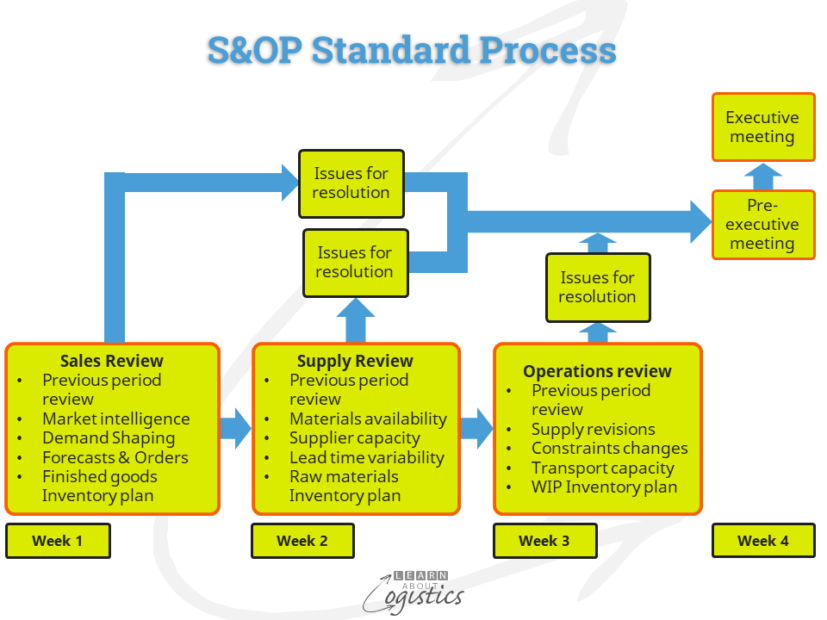

Even though the Sales and Operation Planning (S&OP) concept have been around for a while it is still considered to be an increasingly important planning process in all types of businesses Increased complexity within today's supply chains and uncertainties in market demands are clear motives for this common view0511 · Meeting effectiveness contributes tremendously to the success of a mature S&OP process S&OP meetings typically are the place where relevant information is shared and decisions are made to close gaps in performance As Lora Cecere, founder of Supply Chain Insights, has pointed out, 60% of the success of S&OP comes from behavior and culture change Of course, itS&OP success depends on participation by all functional leaders—such as VPs of product, sales, marketing, supply operations, and finance—to provide a synchronized effort to reach the company's goalsJust as the competitiveness of an eightperson rowing crew would be compromised by an empty seat, the absence of any functional area from the S&OP process

S Op Process Flow Demand Planning

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

· Sales & Operations Planning (S&OP) is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantageDifferent S&OP process flow will be required To help pharmaceutical companies manage this complexity, IT platforms can be used to reduce manual errors and improve process efficiencies Companies should invest in a robust infrastructure that could include, for example, an integrated Enterprise ResourceIt is, however, a top level planning technique to provide overall rates of sales and production, and backlog and finished goods

Change Management Key To Effective S Op Implementation

Sales And Operations Planning Process Flow Page 1 Line 17qq Com

S&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing theThe S&OP process is a broker of informationor to use one of today's common supply chain buzzwords, a 'control tower' A OP team will connect directly on specific topics or action items, but key information, decisions, and plans need to flow through the entire team Thinking about a football analogy, it's similar to a quarterback only telling half of his teammates on the fieldSales and operations planning, often abbreviated to S&OP, is the crossfunctional process of assessing customer buying habits to ensure a company is able to meet the forecasted production, distribution, and purchasing demands required of it

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Scm Complete Process Flow Pdf Document

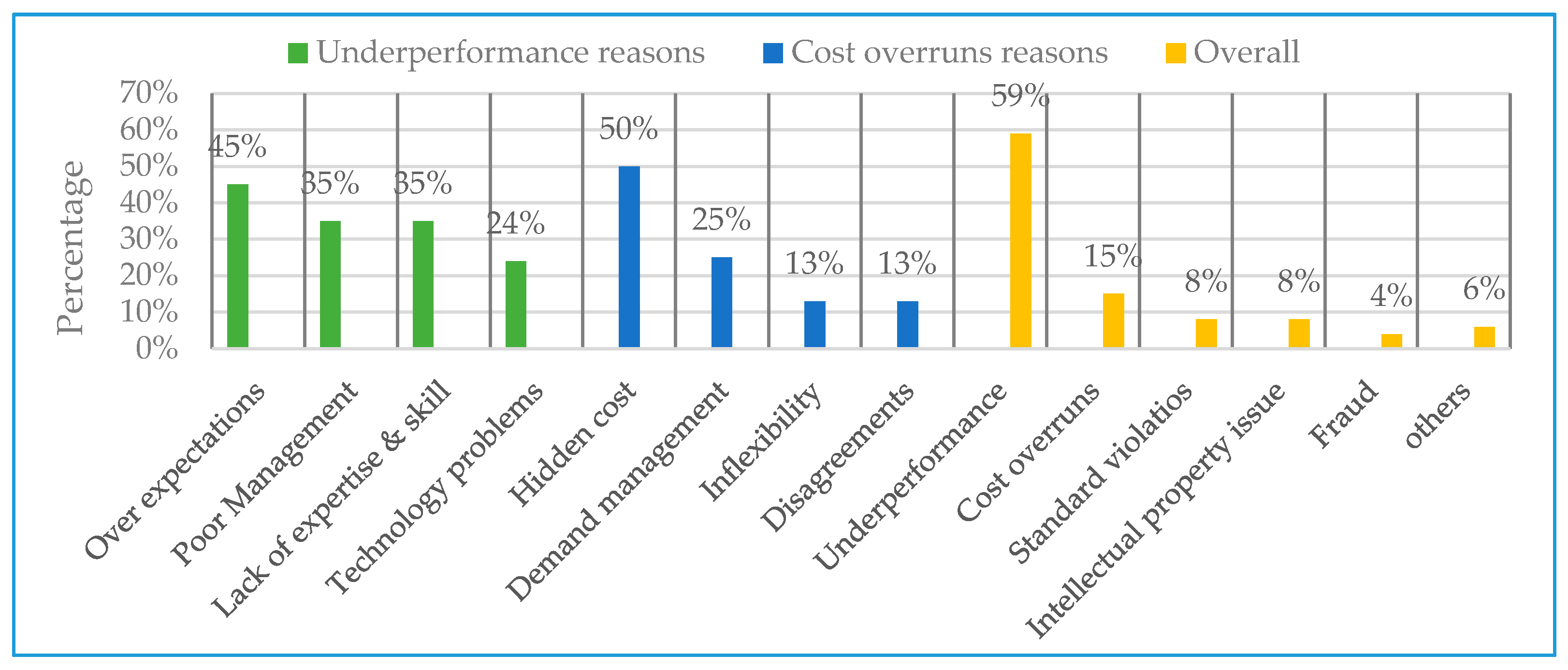

· Sales & Operations Planning (SOP) is a flexible forecasting and planning tool with which sales, production, and other supply chain targets can be set on the basis of historical, existing, and estimated future data Use SOP to streamline and consolidate your company's sales and production operations SOP is particularly suitable for long andResearch around S&OP failures right after the global downturn showed that a third of the respondents didn't have Sales engaged in the S&OP process That was the good news!The next generation of S&OP process will also capitalise on the supply chain as a feedback mechanism of the business environment For example JDA S&OP is tightly coupled to JDA operational modules which means it can report an endto end view of the execution environment back into the S&OP process This highly connected S&OP regime can reach out even beyond the

S Op Sales And Operations Planning And Sco

Sales Operations Planning Introduction Simply Succeed

· S&OP is described as a crossfunctional long term planning process that links different business plans into one integrated set of plans with the main purpose of balancing supply and d mand and linki g the strategic plans to the operational plans of the firm 4 The benefits of S&OP are many and it is claimed that a successful S&OP initiative can improve the accuracy ofSales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and financeAccording to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will communicate changes Effective S&OP

Oracle Advanced Planning Command Center User S Guide

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

· The S&OP process is one I stand by – from startup to Fortune 500 companies The scale of the S&OP process can vary depending on the company size, dynamics, and business model However, the fundamentals of the S&OP process should remain consistent accurate information exchanged crossfunctionally through an organized input/output meeting process flowAlmost half didn't have Operations or Finance engaged Lack of a way to translate between different functional views of information tended to leave one or more participants out of the process Sales wouldGoal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply planning Master planning is concerned with coordinating the supply side of the organization

Educational Videos Ascm 19

Enterra Insights Nine Technologies Transforming The Supply Chain Part 2

· The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a starting point, not much else can happen in the cycle There would be no supply and demand balancing exercise, plan valuation, or scenario2215 · The S&OP process is generally carried out at an aggregate level, often at product family This enables the S&OP process to be agile, focusing on · S&OP Process Flow admin February 1, 18 0 Comments 0 admin The S&OP process has various steps to arrive at a final plan, and it starts with data gathering Related Posts Reducing the Heartburn From Change Management for a New Forecasting & Planning Process Michael Morris January 5, 12 Blockchain In Supply Chains The Good & Bad Ryan Harris

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

While digital tools are undoubtedly the future of S&OP, not all companies currently upgrading their S&OP processes are likely to see major improvements because of digitalization In our experience, going digital may lead to disappointing results if the fundamentals are not robust It is not a "silver bullet" that could somehow magically fix existing issues, but a powerful enhancement thatS&OP process needs a strong foundation and requires the following to be established Establish, in writing, senior management support, clear organizational expectations, longrunning commitment, and positional empowerment · S&OP is a monthly management process that ensures that the company is focused, aligned, and engaged in those efforts the management team collectively decides are the priorities of the enterprise S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change

Sales And Operations Planning Overview Chapter 1 d

Sap Ibp S Op In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

2906 · RapidResponse applications are based on bestpractices and standard process flows established by our years of successful deployments at a multitude of worldleading manufacturers The outofthebox S&OP application enables quick implementations and acts as an advanced starting point for a tailored solution that meets your company's unique sales and operations · Effective BEP is built upon wellestablished foundational processes such as S&OP, PLM & FP&A Business Efficiency Planning is not a novel concept, but part of a continuum of progression towards deeper integration across disparate business functions within the organization to facilitate deeper alignment and maximize business value Business Efficiency Planning seeks to alleviate S&OP processBusiness process flows appear relatively simple compared to other types of processes because they do not provide any conditional business logic or automation beyond providing the streamlined experience for data entry and controlling entry into stages However, when you combine them with other processes and customizations, they can play an important role in saving people time,

S Op Process Flow Diagram Fusebox And Wiring Diagram Device Worry Device Worry Parliamoneassieme It

Oliver Wight Eame Llp What Is Integrated Business Planning

What Is Sales and Operations Planning (S&OP)?0110 · Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted sales

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

S Op More Important For Planning New Era Supply Chains Learn About Logistics

S Op The Evolving Supply Chain Lifeline Supplychainomics

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning S Op 101 Smartsheet

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

Applications Requirements That Assist S Op Decisions Learn About Logistics

Standard Sop Process Flow Sap Blogs

Introducing Sap Ibp S Op Processes Webinar Youtube

S Op Heuristics Flow Chart Download Scientific Diagram

Ultimate Guide To Sales And Operations Planning S Op In 21

S Op Made Good The Importance Of Investing In People Reuters Events Supply Chain Logistics Business Intelligence

A Comprehensive Overview Of Sales And Operations Planning S Op

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Gonzalez Sales And Operations Planning Strategies Marketing Jobs

S Op Process Flow Biel 10 27 11

Ready To Upgrade Your S Op Process For Industry 4 0

A Common S Op Process For Your Business Helps Planning Learn About Logistics

Sales And Operations Planning S Op

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

S Op Application Flow At A Glance Sc Navigator

A Case Method For Sales And Operations Planning A Learning Experience From Germany

What Is S Op How S Op Works Demand Planning Com

Logistics Free Full Text The Integration Of Extended Supply Chain With Sales And Operation Planning A Conceptual Framework Html

Sales Operations Planning A Proven Business Process Learn About Logistics

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Process Post1 New Product Planning Process Oracle Value Chain Planning Blog

S Op Families By Constraint

S Op Software Sales And Operations Planning Qad Dynasys

What Is S Op How S Op Works Demand Planning Com

S Op S Oe The Key To Driving Supply Chain Agility

What Is Integrated Supply Chain Planning Logistics Viewpoints

Demand And Supply Management In Uncertain Times

Diagram S Op Process Flow Diagram Full Version Hd Quality Flow Diagram Diagramate Usrdsicilia It

What Is Sales And Operations Planning S Op Plex Demandcaster

The S Op Lean Connection Making Lean Work With Demand Variability Ppt Download

Aktuelles Von Aca Solutions Sales And Operations Planning To Industrialize The Aerospace Supply Chain

The Production Planning Pp Or Sales And Operations Planning S Op Download Scientific Diagram

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

File Monthly S Op Process Jpg Wikipedia

What Is One Plan S Op Arkieva

Ultimate Guide To Sales And Operations Planning S Op In 21

S P Process Flow Demand Planning

Sales And Operations Planning Relex Solutions

Integrating The S Op Process Go With The Flow Sales And Operations Planning Master Schedule Process

Using Retail S Op To Make The Holiday Season Smoother And More Profitable

Supply Chain Logistics Best Practice Insights Publications Resources Gra

Sales Operations Planning Consulting Supply Velocity

Order To Cash Intrigo

Gartner Blog Network

Sales And Operations Planning Relex Solutions

How To Select The Best Sales And Operations Planning S Op Software For Your Business In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Seven Steps To Support A Sustainable S Op Culture Supply Chain Minded

Sales And Operations Planning An Exploratory Study And Framework Emerald Insight

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Sales Operations Planning Scpi

Mrp And Sop Definition And Flow

Oracle Advanced Planning Command Center User S Guide

Supply Chain Management Wikipedia

S Op Process

Sales And Operations Planning Powerpoint Template Sketchbubble

S Op Process

S Op Process

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Toc4u Focus 17

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Integrating Suppliers In Sales Operations Planning Gep

Dp Vs S Op Process Flow

0 件のコメント:

コメントを投稿